This lesson explores how engineers work to solve the challenges of a society, such as moving goods and people. Students work in teams to devise a conveyor system using everyday materials that can move pieces of candy.

- Learn about engineering design and redesign.

- Learn about manufacturing processes and conveyor systems.

- Learn how engineering can help solve society’s challenges.

- Learn about teamwork and problem solving.

Age Levels: 8-18

Materials & Preparation

Build Materials (For each team)

Recommended Materials – All or some may be used for Trading/Table of Possibilities

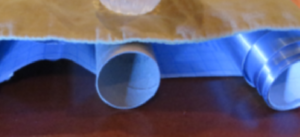

- Cardboard tubes (paper towel rolls, toilet paper rolls)

- Empty water/soda bottles

- Hoses or tubes

- PVC piping

- Pencils

- Rubber bands

- Ball bearings

- Rubber or plastic balls

- Fabric sheets

- String

- Gears

- Paper/plastic cups

- Straws

- Paper towels

- Paper clips

- Glue

- String

- Aluminum foil

- Plastic wrap

- Rolls of wrapping paper

Testing Materials

- Pieces of candy or similar sized items (each team should use the same items)

Testing Materials & Process

VanVoorhis

Materials

- Pieces of candy or similar sized items (each team should use the same items)

Process

Each team tests their conveyor belt designs by demonstrating how the conveyor moves candy (or other small items) along a 4 foot distance, including along a 90 degree turn.

Engineering Design Challenge

Design Challenge

Move pieces of candy 4 feet (120cm) including a 90 degree turn.

You are part of a team of engineers given the challenge of developing your own conveyor belt. You will need to move candy along your belt which has to include a 90 degree turn.

Criteria

- Candy must move 4 feet.

- Design must include a 90 degree turn.

Constraints

- Candy cannot be glued or affixed to the belt surface.

- Candy cannot fall off.

- Use only the materials provided.

- Teams may trade unlimited materials.

Activity Instructions & Procedures

- Break class into teams of 3-4.

- Hand out the Conveyor Engineering worksheet, as well as some sheets of paper for sketching designs.

- Discuss the topics in the Background Concepts Section. To introduce the lesson, consider asking students how an airport sorts and delivers luggage. Ask them to think about any “moving sidewalks” they have traveled on (airports, malls, other large buildings).

- Review the Engineering Design Process, Design Challenge, Criteria, Constraints and Materials.

- Provide each team with their materials.

- Explain that students must design and build a working conveyor belt. The conveyor must move candy 4 feet and include a 90 degree turn.

- Announce the amount of time they have to design and build (1 hour recommended).

- Use a timer or an on-line stopwatch (count down feature) to ensure you keep on time. (www.online-stopwatch.com/full-screen-stopwatch). Give students regular “time checks” so they stay on task. If they are struggling, ask questions that will lead them to a solution quicker.

- Students meet and develop a plan for their conveyor belt. They agree on materials they will need, write/draw their plan, and present their plan to the class. Teams may trade unlimited materials with other teams to develop their ideal parts list.

- Teams build their designs.

- Test the designs by demonstrating how it moves candy (or other small items) along for 4 feet, including along a 90 degree turn.

- As a class, discuss the student reflection questions.

- For more content on the topic, see the “Digging Deeper” section.

Extension Idea

Have advanced or older students power their conveyor systems with motors or gear systems.

Student Reflection (engineering notebook)

- How similar was your original design to the actual conveyor your team built?

- If you found you needed to make changes during the construction phase, describe why your team decided to make revisions.

- Which conveyor system that another team engineered was the most interesting to you? Why?

- Do you think that this activity was more rewarding to do as a team, or would you have preferred to work alone on it? Why?

- If you could have used one additional material (tape, glue, wood sticks, foil — as examples) which would you choose and why?

Time Modification

The lesson can be done in as little as 1 class period for older students. However, to help students from feeling rushed and to ensure student success (especially for younger students), split the lesson into two periods giving students more time to brainstorm, test ideas and finalize their design. Conduct the testing and debrief in the next class period.

Engineering Design Process

Background Concepts

tecksiong-bigstock.com

What is a Conveyor Belt?

Conveyor belts can be made out of many different materials, but in its most basic form is a frame with rollers installed that move materials on top. It can be motorized so that the rollers move at a set speed, be manually powered, or move with the force of gravity.

There is also an application called a sandwich belt in which two basic conveyors run in parallel — one on top of the other, leaving enough space to sandwich a box between. It is used frequently to move items up steep inclines and was developed in 1979 to improve efficiency when removing rocks and other materials from mines.

Who uses conveyor systems?

Conveyor systems are commonly used in many industries, including shipping, automotive, agricultural, computer, electronic, food processing, aerospace, pharmaceutical, chemical, bottling and canning, and packaging. Although most materials can be conveyed, some of the most common include food items in boxes, bottles, and cans; automotive components; mining materials and scrap; and grain or animal feed. They are also used to move people and materials (such as boxes and luggage) at airports. A common installation site for conveyor belts are packaging departments and also throughout manufacturing areas. Belts are usually installed at waist height to make it easier for people to oversee the operation and observe materials moving through the system. And…in many countries sushi restaurants are using conveyor belts to route dishes of sushi through customer tables, so they just see what goes by and pick up the plate that looks good!

How does it work?

A conveyor system usually consists of a metal frame with rollers installed at various intervals along the length of the conveyor belt. Usually these are covered with a smooth or rubbery material that covers the rollers and helps materials move along without being stuck between rollers. Some roller systems are straight and some are curved. Some are flat, and some move materials up or down between floors or even into underground mines.

What is mass production?

Mass Production involves making many copies of products, very quickly, using assembly line techniques to send partially complete products to workers who each work on an individual step, rather than having a worker work on a whole product from start to finish.

Conveyor Belt History and Assembly Line

Baloncici-bigstock.com

History and Inventors

Primitive conveyor belts have been in use since the 1800s — initially used in transporting goods to and from mines, which had a great impact on improving the speed with which mined materials could be brought to the surface. In 1913, Henry Ford introduced conveyor belt assembly lines at Ford Motor Company’s Highland Park, Michigan, US factory. The assembly line developed by Ford Motor Company between 1908 and 1915 made assembly lines famous in the following decade through the social ramifications of mass production — and the conveyor belt was a key component of the system, allowing parts to be moved in from workers.

vinap-bigstock.com

In 1957, the B. F. Goodrich Company patented a conveyor belt ultimately called the Turnover Conveyor Belt System. It incorporated a half-twist on the belt called a Möbius Strip (see diagram at right). This design had a big advantage over conventional belts because it exposed all of its surface area to wear and tear and so lasted longer. Now, möbius strip belts are no longer manufactured because untwisted modern belts made from several layers of materials are more durable.

The longest belt conveyor system in the world as of 2012 is 98 km long, connecting the phosphate mines of Bu Craa to the Western Sahara coast. For baggage applications, the longest conveyor system at 92 km is in the Dubai International Airport.

arenacreative-bigstock.com

Moving Sidewalks

Another type of conveyor system is the moving sidewalk, which transports people instead of goods or suitcases! The first moving walkway debuted at the World’s Columbian Exposition of 1893, in Chicago, IL, US. Now these transport systems are used in airports, malls, and any area where people may be expected to walk long distances. The first moving walkway in an airport was installed in 1958 at Love Field in Dallas, Texas, US. The animated TV series The Jetsons depicts moving walkways everywhere, even in private homes.

Vocabulary

- Constraints: Limitations with material, time, size of team, etc.

- Conveyor Belt: A frame with rollers installed that move materials on top.

- Criteria: Conditions that the design must satisfy like its overall size, etc.

- Engineers: Inventors and problem-solvers of the world. Twenty-five major specialties are recognized in engineering (see infographic).

- Engineering Design Process: Process engineers use to solve problems.

- Engineering Habits of Mind (EHM): Six unique ways that engineers think.

- Iteration: Test & redesign is one iteration. Repeat (multiple iterations).

- Mass Production: Involves making many copies of products, very quickly, using assembly line techniques to send partially complete products to workers who each work on an individual step, rather than having a worker work on a whole product from start to finish.

- Prototype: A working model of the solution to be tested.

- Sandwich Belt: Two basic conveyors run in parallel — one on top of the other, leaving enough space to sandwich a box between.

Dig Deeper

Internet Connections

Recommended Reading

- Conveyors: Application, Selection, and Integration (Industrial Innovation) (ISBN: 978-1439803882)

- The Invention of the Moving Assembly Line: A Revolution in Manufacturing (ISBN: 978-1604137729)

- From the American System to Mass Production, 1800-1932: The Development of Manufacturing Technology in the United States (ISBN: 978-0801829758)

Writing Activity

Write an essay or a paragraph about three existing and one imagined application of a conveyor belt system.

Curriculum Alignment

Alignment to Curriculum Frameworks

Note: Lesson plans in this series are aligned to one or more of the following sets of standards:

- U.S. Science Education Standards (http://www.nap.edu/catalog.php?record_id=4962)

- U.S. Next Generation Science Standards (http://www.nextgenscience.org/)

- International Technology Education Association’s Standards for Technological Literacy (http://www.iteea.org/TAA/PDFs/xstnd.pdf)

- U.S. National Council of Teachers of Mathematics’ Principles and Standards for School Mathematics (http://www.nctm.org/standards/content.aspx?id=16909)

- U.S. Common Core State Standards for Mathematics (http://www.corestandards.org/Math)

- Computer Science Teachers Association K-12 Computer Science Standards (http://csta.acm.org/Curriculum/sub/K12Standards.html)

National Science Education Standards Grades K-4 (ages 4-9)

CONTENT STANDARD A: Science as Inquiry

As a result of activities, all students should develop

- Abilities necessary to do scientific inquiry

- Understanding about scientific inquiry

CONTENT STANDARD B: Physical Science

As a result of the activities, all students should develop an understanding of

- Properties of objects and materials

- Position and motion of objects

CONTENT STANDARD E: Science and Technology

As a result of activities, all students should develop

- Abilities of technological design

- Understanding about science and technology

CONTENT STANDARD F: Science in Personal and Social Perspectives

As a result of activities, all students should develop understanding of

- Types of resources

- Science and technology in local challenges

CONTENT STANDARD G: History and Nature of Science

As a result of activities, all students should develop understanding of

- Science as a human endeavor

National Science Education Standards Grades 5-8 (ages 10-14)

CONTENT STANDARD A: Science as Inquiry

As a result of activities, all students should develop

- Abilities necessary to do scientific inquiry

CONTENT STANDARD B: Physical Science

As a result of their activities, all students should develop an understanding of

- Properties and changes of properties in matter

- Motions and forces

CONTENT STANDARD E: Science and Technology

As a result of activities in grades 5-8, all students should develop

- Abilities of technological design

CONTENT STANDARD F: Science in Personal and Social Perspectives

As a result of activities, all students should develop understanding of

- Risks and benefits

- Science and technology in society

National Science Education Standards Grades 5-8 (ages 10-14)

CONTENT STANDARD G: History and Nature of Science

As a result of activities, all students should develop understanding of

- Science as a human endeavor

- History of science

National Science Education Standards Grades 9-12 (ages 14-18)

CONTENT STANDARD A: Science as Inquiry

As a result of activities, all students should develop

- Abilities necessary to do scientific inquiry

CONTENT STANDARD B: Physical Science

As a result of their activities, all students should develop understanding of

- Motions and forces

- Conservation of energy and increase in disorder

- Interactions of energy and matter

CONTENT STANDARD E: Science and Technology

As a result of activities, all students should develop

- Abilities of technological design

- Understandings about science and technology

CONTENT STANDARD F: Science in Personal and Social Perspectives

As a result of activities, all students should develop understanding of

- Personal and community health

- Science and technology in local, national, and global challenges

CONTENT STANDARD G: History and Nature of Science

As a result of activities, all students should develop understanding of

- Historical perspectives

Next Generation Science Standards – (Ages 8-11)

Motion and Stability: Forces and Interactions

Students who demonstrate understanding can:

- 3-PS2-1. Plan and conduct an investigation to provide evidence of the effects of balanced and unbalanced forces on the motion of an object.

Engineering Design

Students who demonstrate understanding can:

- 3-5-ETS1-1.Define a simple design problem reflecting a need or a want that includes specified criteria for success and constraints on materials, time, or cost.

- 3-5-ETS1-2.Generate and compare multiple possible solutions to a problem based on how well each is likely to meet the criteria and constraints of the problem.

- 3-5-ETS1-3.Plan and carry out fair tests in which variables are controlled and failure points are considered to identify aspects of a model or prototype that can be improved.

Next Generation Science Standards – (Ages 11-14)

Engineering Design

- MS-ETS1-2 Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem.

Standards for Technological Literacy – All Ages

The Nature of Technology

- Standard 1: Students will develop an understanding of the characteristics and scope of technology.

Technology and Society

- Standard 4: Students will develop an understanding of the cultural, social, economic, and political effects of technology.

- Standard 6: Students will develop an understanding of the role of society in the development and use of technology.

- Standard 7: Students will develop an understanding of the influence of technology on history.

Design

- Standard 8: Students will develop an understanding of the attributes of design.

- Standard 9: Students will develop an understanding of engineering design.

- Standard 10: Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

Abilities for a Technological World

- Standard 11: Students will develop abilities to apply the design process.

- Standard 13: Students will develop abilities to assess the impact of products and systems.

The Designed World

- Standard 18: Students will develop an understanding of and be able to select and use transportation technologies.

Related Engineering Fields and Degrees

Student Worksheet

Engineering Teamwork and Planning

Rost-9-bigstock.com

You are part of a team of engineers given the challenge of developing your own conveyor belt out of a range of materials. You will need to convey candy along your belt which has to include a 90 degree turn. You can use any materials you like that are provided to you….and can share or trade materials with other student teams. There are a few rules: 1. Candy cannot be glued or affixed to the belt surface, 2. Candy cannot fall off.

Research Phase

Read the materials provided to you by your teacher. If you have access to the internet, explore examples of conveyor systems and consider how groceries are moved along to the cashier in a market or grocery store.

Planning and Design Phase

Draw a diagram of your planned conveyor belt on the back of this page and make a list and quantity of all the materials you think you will need in the box below. You’ll need to consider how you will make the conveyor belt move — you can use your hands to move rollers, gears, or you could use a motor — just don’t touch the cup!

Materials you will need:

Presentation Phase

Present your plan and drawing to the class, and consider the plans of other teams. You may wish to fine tune your own design.

Build it! …and Redesign if you need to!

Next build your conveyor belt and test it. You may share unused building materials with other teams, and trade materials too. Be sure to watch what other teams are doing and consider the aspects of different designs that might be an improvement on your team’s plan.

Test it!

Next, the class will test their conveyor belt systems. Be sure to watch all the tests so you can see the advantages or disadvantages of other systems.

Reflection

Complete the reflection questions below:

- How similar was your original design to the actual conveyor your team built?

- If you found you needed to make changes during the construction phase, describe why your team decided to make revisions.

- Which conveyor system that another team engineered was the most interesting to you? Why?

- Do you think that this activity was more rewarding to do as a team, or would you have preferred to work alone on it? Why?

- If you could have used one additional material (tape, glue, wood sticks, foil — as examples) which would you choose and why?

Translations

Industrial Engineering

Industrial Engineering

Computer Engineering

Computer Engineering