Clipper Creations

In this lesson students learn about simple machines. Students design and build a working model of a nail clipper.

- Explore the basic principles of engineering design.

- Learn how to build a model of a simple machine.

- Explore how a simple machine such as a nail clipper works.

Age Levels: 8-18

Build Materials

Required Materials

- Foam board sheets

- Scotch tape

- Glue

- Toothpicks

- Box cutter

Model Components

- Bottom clipper board

- Top clipper board

- Hand lever to operate clippers

- Part of a pencil to serve as a shaft

- Foam board wedge for end where clipper boards come together (pre-cut by teacher)

- Double-thick fulcrum for hand lever

- 8 clipper edges (represent cutting edges of real clippers)

- 10 toothpicks to form ends of pencil shaft

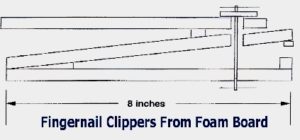

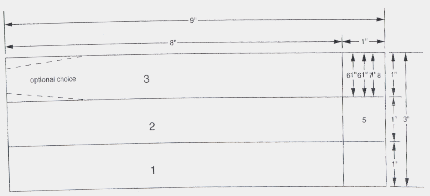

In advance, the teacher should cut out foam board per the diagram below, providing students with pre-cut shapes. Students then assemble small parts to large parts provided with glue. Allow the glue to dry. The next day or class period, students should assemble the clipper model with tape at the edge end of both the bottom and top clipper boards. Slide toothpicks through holes in the pencil, or tape them to the pencil.

Materials

- Nail clipper models

Process

- Students test out their nail clipper models by operating them to simulate cutting fingernails

Design Challenge

You are a team of engineers given the challenge of building a working model of a set of nail clippers using the materials provided. Once you’ve completed your model, test your design to simulate cutting your fingernails.

Next, you will have the challenge of devising a plan using simple machines to move a phone book from one side of the classroom to the other without touching the book. You must use at least one simple machine in your solution…but may use as many as you like.

Criteria

- Follow the instructions outlined on the Student Worksheet to build the model

Constraints

- Use only the materials provided

- Break class into teams of 2.

- Hand out the Clipper Creations worksheet.

- Discuss the topics in the Background Concepts Section. Highlight types of simple machines, paying close attention to the “lever.” Instruct students to use the Student Worksheet as a guide to assembling their nail clipper models.

- Review the Engineering Design Process, Design Challenge, Criteria, Constraints and Materials.

- Provide each team with their materials.

- Explain that students must build a working model of a set of nail clippers.

- Announce the amount of time they have to build (1 hour recommended).

- Use a timer or an on-line stopwatch (count down feature) to ensure you keep on time. (www.online-stopwatch.com/full-screen-stopwatch). Give students regular “time checks” so they stay on task. If they are struggling, ask questions that will lead them to a solution quicker.

- Students meet and build their models using the instructions and diagrams shown in the Student Worksheet

- Teams build their designs.

- Teams test their designs by simulating how the nail cutter will cut their fingernails.

- After completing the model build, instruct student teams to devise a plan using simple machines to move a phone book from one side of the classroom to the other without touching the book. They must use at least one simple machine in their solution…but may use many as they like. They should sketch their plan.

- As a class, discuss the student reflection questions.

- For more content on the topic, see the “Digging Deeper” section.

Student Reflection (engineering notebook)

- What was the most effective part of your design — the part that worked as planned?

- What was the least effective part of your design — the part that caused the most trouble or didn’t work as you had planned?

- If you could redo your original plan, what would you change?

- Do you think engineers have to design and redesign and redesign in order to come up with the best product or process? Give an example of a product or process that has changed over time (such as telephones or airplanes).

Time Modification

The lesson can be done in as little as 1 class period for older students. However, to help students from feeling rushed and to ensure student success (especially for younger students), split the lesson into two periods giving students more time to brainstorm, test ideas and finalize their design. Conduct the testing and debrief in the next class period.

Teacher Resource

| SIMPLE MACHINES | WHAT IT IS | HOW IT HELPS US WORK | EXAMPLES |

| LEVER

|

A stiff bar that rests on a support called a fulcrum

|

Lifts or moves loads

|

Nail clipper, shovel, nutcracker, seesaw, crow-bar, elbow, tweezers, bottle opener

|

| INCLINED PLANE

|

A slanting surface connecting a lower level to a higher level

|

Things move up or down it

|

Slide, stairs, ramp, escalator, slope

|

| WHEEL AND AXLE

|

A wheel with a rod, called an axel, through its center: both parts move together

|

Lifts or moves loads

|

Doorknob, pencil sharpener, bike

|

| PULLEY

|

A grooved wheel with a rope or cable around it

|

Moves things up, down, or across

|

Curtain rod, tow truck, mini-blind, flag pole, crane

|

Typically, machines are intended to reduce the amount of force required to move an object. But in the process, the distance is increased. A wheel chair ramp is easily visualized example of this relationship. While the amount of effort and strength is reduced (force) the actual distance is significantly increased. Therefore, the amount of actual work is the same. While the typical application of machines is to reduce effort or force, there are important applications of machines where this is no advantage – that is force is not reduced, or there is actually a decrease in advantage – that is, force is increased. The best example of a machine that provides no advantage is a simple or single pulley. A single pulley only changes the direction of the effort force. A curtain pull is an example.

Nail clippers are an example of levers. The force exerted on the handle of the clippers compresses the blades of the clippers so the blades touch and trim the nail. In a nail clipper, the fulcrum is the pivot joint between the two parts of the clipper.

Introduction to Simple Machines

Simple machines are “simple” because most have only one moving part. When you put simple machines together, you get a complex machine, like a lawn mower, a car, even an electric nose hair trimmer! Remember, a machine is any device that makes work easier. In science, “work” means making something move. It’s important to know that when you use a simple machine, you’re actually doing the same amount of work — it just seems easier. A simple machine reduces the amount of effort needed to move something, but you wind up moving it a greater distance to accomplish the same amount of work. So remember, there’s a trade–off of energy when using simple machines.

Typically, machines are intended to reduce the amount of force required to move an object. But in the process, the distance is increased. A wheel chair ramp is easily visualized example of this relationship. While the amount of effort and strength is reduced (force) the actual distance is significantly increased. Therefore, the amount of actual work is the same. While the typical application of machines is to reduce effort or force, there are important applications of machines where this is no advantage – that is force is not reduced, or there is actually a decrease in advantage – that is, force is increased. The best example of a machine that provides no advantage is a simple or single pulley. A single pulley only changes the direction of the effort force. A curtain pull is an example.

Nail clippers are an example of levers. The force exerted on the handle of the clippers compresses the blades of the clippers so the blades touch and trim the nail. In a nail clipper, the fulcrum is the pivot joint between the two parts of the clipper.

Types of Simple Machines

There are four types of simple machines which form the basis for all mechanical machines:

Lever

Try pulling a really stubborn weed out of the ground. Using just your bare hands, it might be difficult or even painful. With a tool, like a hand shovel, however, you should win the battle. Any tool that pries something loose is a lever. A lever is an arm that “pivots” (or turns) against a “fulcrum” (or point). Think of the claw end of a hammer that you use to pry nails loose. It’s a lever. It’s a curved arm that rests against a point on a surface. As you rotate the curved arm, it pries the nail loose from the surface. And that’s hard work! There are three kinds of levers:

- First Class Lever – When the fulcrum lies between the force arm and the lever arm, the lever is described as a first class lever. In fact many of us are familiar with this type of lever. It is the classic teeter-totter example – or a nail clipper.

- Second Class Lever – In the second class lever, the load arm lies between the fulcrum and the force arm. A good example of this type of lever is the wheelbarrow.

- Third Class Lever – In this class of levers, the force arm lies between the fulcrum and the load arm. Because of this arrangement, a relatively large force is required to move the load. This is offset by the fact that it is possible to produce movement of the load over a long distance with a relatively small movement of the force arm. Think of a fishing rod!

Inclined Plane

A plane is a flat surface. For example, a smooth board is a plane. Now, if the plane is lying flat on the ground, it isn’t likely to help you do work. However, when that plane is inclined, or slanted, it can help you move objects across distances. And, that’s work! A common inclined plane is a ramp. Lifting a heavy box onto a loading dock is much easier if you slide the box up a ramp–a simple machine.

Wedge

- Instead of using the smooth side of the inclined plane, you can also use the pointed edges to do other kinds of work. For example, you can use the edge to push things apart. Then, the inclined plane is a wedge. So, a wedge is actually a kind of inclined plane. An axeblade is a wedge. Think of the edge of the blade. It’s the edge of a smooth slanted surface. That’s a wedge!

Screw

- Now, take an inclined plane and wrap it around a cylinder. Its sharp edge becomes another simple tool: the screw. Put a metal screw beside a ramp and it’s kind of hard to see the similarities, but the screw is actually just another kind of inclined plane. How does the screw help you do work? Every turn of a metal screw helps you move a piece of metal through a wooden space.

Wheel and Axle

A wheel is a circular disk attached to a central rod, called an axle. The steering wheel of a car is a wheel and axle. The section that we place our hands on and apply force (torque) is called the wheel, which turns the smaller axle. The screwdriver is another example of the wheel and axle. Loosening a tight screw with bare hands can be impossible. The thick handle is the wheel, and the metal shaft is the axle. The larger the handle, the less force is needed to turn the screw.

Pulley

Instead of an axle, the wheel could also rotate a rope or cord. This variation of the wheel and axle is the pulley. In a pulley, a cord wraps around a wheel. As the wheel rotates, the cord moves in either direction. Now, attach a hook to the cord, and you can use the wheel’s rotation to raise and lower objects. On a flagpole, for example, a rope is attached to a pulley. On the rope, there are usually two hooks. The cord rotates around the pulley and lowers the hooks where you can attach the flag. Then, rotate the cord and the flag raises high on the pole.

Recommended Reading

- Making Mechanical Marvels In Wood (ISBN: 978-1626548862)

- Science Experiments With Simple Machines (Science Experiments) by Sally Nankivell-Aston, Dorothy Jackson (ISBN: 978-0531154458)

Writing Activity

Identify examples of other designs of nail clippers. Write an essay (or paragraph depending on age) about how the designs differ, and how the different designs might impact the function of the clipper.

Alignment to Curriculum Frameworks

Note: All lesson plans in this series are aligned to the National Science Education Standards which were produced by the National Research Council and endorsed by the National Science Teachers Association, and if applicable, also to the International Technology Education Association’s Standards for Technological Literacy or the National Council of Teachers of Mathematics’ Principles and Standards for School Mathematics.

National Science Education Standards Grades K-4 (ages 4 – 9)

CONTENT STANDARD A: Science as Inquiry

As a result of activities, all students should develop

- Abilities necessary to do scientific inquiry

- Understanding about scientific inquiry

CONTENT STANDARD E: Science and Technology

As a result of activities, all students should develop

- Abilities of technological design

CONTENT STANDARD F: Science in Personal and Social Perspectives

As a result of activities, all students should develop understanding of

- Science and technology in local challenges

CONTENT STANDARD G: History and Nature of Science

As a result of activities, all students should develop understanding of

- Science as a human endeavor

National Science Education Standards Grades 5-8 (ages 10 – 14)

CONTENT STANDARD A: Science as Inquiry

As a result of activities, all students should develop

- Abilities necessary to do scientific inquiry

- Understandings about scientific inquiry

CONTENT STANDARD E: Science and Technology

As a result of activities in grades 5-8, all students should develop

- Abilities of technological design

- Understandings about science and technology

CONTENT STANDARD F: Science in Personal and Social Perspectives

As a result of activities, all students should develop understanding of

- Risks and benefits

- Science and technology in society

CONTENT STANDARD G: History and Nature of Science

As a result of activities, all students should develop understanding of

- Science as a human endeavor

- History of science

National Science Education Standards Grades 9-12 (ages 14-18)

CONTENT STANDARD A: Science as Inquiry

As a result of activities, all students should develop

- Abilities necessary to do scientific inquiry

- Understandings about scientific inquiry

CONTENT STANDARD E: Science and Technology

As a result of activities, all students should develop

- Abilities of technological design

- Understandings about science and technology

CONTENT STANDARD F: Science in Personal and Social Perspectives

As a result of activities, all students should develop understanding of

- Personal and community health

- Science and technology in local, national, and global challenges

CONTENT STANDARD G: History and Nature of Science

As a result of activities, all students should develop understanding of

- Nature of scientific knowledge

- Historical perspectives

Standards for Technological Literacy – All Ages

The Nature of Technology

- Standard 1: Students will develop an understanding of the characteristics and scope of technology.

Technology and Society

- Standard 4: Students will develop an understanding of the cultural, social, economic, and political effects of technology.

- Standard 6: Students will develop an understanding of the role of society in the development and use of technology.

- Standard 7: Students will develop an understanding of the influence of technology on history.

Design

- Standard 8: Students will develop an understanding of the attributes of design.

- Standard 9: Students will develop an understanding of engineering design.

- Standard 10: Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

Abilities for a Technological World

- Standard 13: Students will develop abilities to assess the impact of products and systems.

The Designed World

Standard 17: Students will develop an understanding of and be able to select and use information and communication technologies.

Build a Model of a Nail Clipper

Materials List

- foam board

- scotch tape

- toothpicks

Parts of the Model

- Bottom clipper board

- Top clipper board

- Hand lever to operate clippers

- Part of a pencil to serve as a shaft

- Foam board wedge for end where clipper boards come together (precut by teacher)

- Double-thick fulcrum for hand lever

- 8 clipper edges (represent cutting edges of real clippers)

- 10 toothpicks to form ends of pencil shaft

Instructions

Working in teams, examine the following illustration, and assemble small parts to large parts provided with glue. Allow the glue to dry. Next, assemble the clipper model with tape at the edge end of both the bottom and top clipper boards. Slide toothpicks through holes in the pencil, or tape them to the pencil. Test your clippers!

You are the engineer! Work in a team and devise a plan using simple machines to move a phone book from one side of the classroom to the other without touching the book. You must use at least one simple machine in your solution…but may use many if you like.

Step One:

Draw your team’s machine or solution in the box below.

|

|

Step Two:

Try out your team’s plan and see if it works!

Questions:

- What was the most effective part of your design — the part that worked as planned?

- What was the least effective part of your design — the part that caused the most trouble or didn’t work as you had planned?

- If you could redo your original plan, what would you change?

- Do you think engineers have to design and redesign and redesign in order to come up with the best product or process? Give an example of a product or process that has changed over time (such as telephones or airplanes).

Lesson Plan Translation

Industrial Engineering

Industrial Engineering

Computer Engineering

Computer Engineering